What Causes Garage Door Spring Failures in Bethel Park PA?

Cause of Spring Failure | Percentage of Reported Cases |

Metal fatigue from daily cycles | 41% |

Corrosion and moisture exposure | 22% |

Improper spring sizing | 15% |

Lack of lubrication | 12% |

Installation imbalance issues | 10% |

How Cable Breaks Happen and Why They’re Dangerous for Homeowners

- Bent bottom brackets from uneven tension

- Warped door sections from torsional stress

- Motor gear wear due to lifting resistance

- Sensor misalignment caused by door tilt

Warning Signs Your Garage Door Springs or Cables Are About to Fail

- Loud snapping or popping sounds during door operation

- Uneven door movement, where one side rises faster than the other

- The door slams shut instead of lowering smoothly

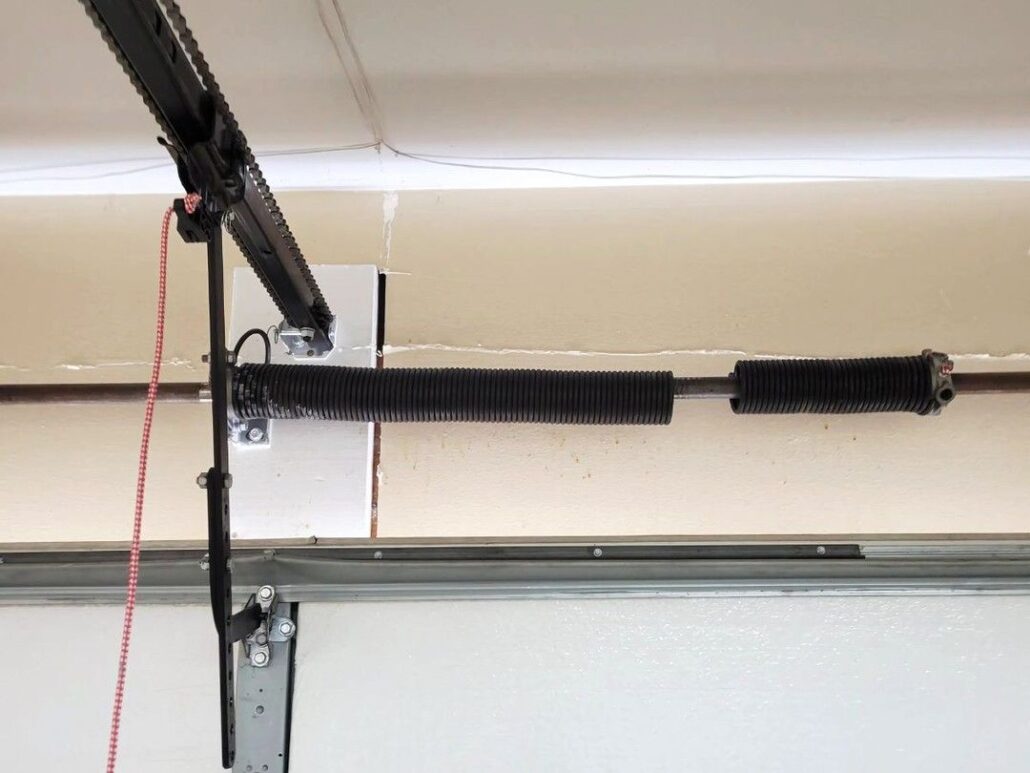

- Visible gaps in torsion springs, indicating coil separation

- Frayed cable strands near bottom brackets or drums

- A jerky or stuttering motion when opening

- Excessive vibration in tracks or support brackets

- The door feels unusually heavy during manual operation

Repair vs Replace: When Bethel Park PA Homeowners Should Upgrade Components

How Much Does Spring and Cable Repair Cost in Bethel Park PA?

Service Type

| Average 2026 Cost Range

|

Single torsion spring replacement

| $180 – $350

|

Dual spring replacement set

| $280 – $520

|

Cable replacement (pair)

| $150 – $300

|

Emergency same-day service

| Additional $75 – $150

|

System rebalancing and calibration

| $90 – $180

|

Safety Tips to Prevent Garage Door Spring and Cable Accidents

How Professional Garage Door Repair Bethel Park PA Services Can Help Protect Your Home

Service Information & Answers

Worn springs and cables are the leading causes, often due to daily use and seasonal temperature changes. Fixing them early prevents unsafe door movement and bigger repairs.

Early signs include frayed strands, rust spots, slack in the cable, uneven door movement, or a crooked lift. These symptoms indicate rising tension imbalance and should be inspected promptly.

Most spring issues require replacement rather than repair. Springs weaken internally from cycle fatigue, and repairing them doesn’t restore lost strength or long-term safety.

Yes. When springs lose tension, cables experience increased stress, leading to accelerated wear or sudden failure. Addressing both components together is often the safest solution.

Annual inspections are recommended, especially in high-use homes. Regular evaluations help detect tension loss, corrosion, and uneven wear before they lead to dangerous failures.