Choosing the Right Garage Door Opener in Pittsburgh PA 2026

Why Opener Selection Matters More Than Ever

Key Factors That Influence Opener Performance

- Motor horsepower and torque capacity

- Drive system design and friction level

- Door weight and balance condition

- Frequency of daily operation

- Smart control and automation stability

Understanding Motor Strength and Door Load

Long-Term Reliability Starts with Proper Matching

Signs an Opener Is Not Properly Matched

- Slower opening or closing speed

- Increased vibration during operation

- Opener motor running hotter than usual

- Door hesitating at mid-travel

- Gradual increase in operational noise

The Value of Proper Opener Selection

Top Garage Door Opener Brands Performance and Reliability Comparison 2026

What Defines a Reliable Garage Door Opener

Performance Factors That Separate Opener Quality

- Motor efficiency and heat management

- Gear durability and wear resistance

- Motion smoothness under load

- Automation response consistency

- Vibration control and noise reduction

Long-Term Reliability Patterns in Modern Openers

Key Performance Observations

- Stable openers maintain consistent motion speed

- Efficient motors produce less vibration and noise

- Balanced torque reduces gear strain

- Improved cooling prevents overheating

- Smooth drive operation lowers mechanical stress

Opener Installation and Performance Consistency

The Role of Quality Engineering in Daily Reliability

Garage Door Opener Installation Pittsburgh PA Opener Compatibility and Requirements

Why Compatibility Determines Long-Term Performance

Structural Requirements for Proper Opener Installation

Electrical and Power Compatibility

Key Compatibility Checks During Installation

- Door balance and spring calibration

- Adequate structural clearance for opener placement

- Stable electrical supply and proper grounding

- Smooth track and roller movement

- Correct force and travel calibration

Installation Timeline and Performance Factors

Installation Step

| Purpose

| Impact on Performance

|

Door balance check

| Ensures even load

| Reduces motor strain

|

Structural mounting

| Stabilizes opener

| Improves motion control

|

Electrical setup

| Provides steady power

| Prevents signal issues

|

Force calibration

| Controls lifting pressure

| Enhances smoothness

|

Final testing

| Verifies operation

| Confirms reliability

|

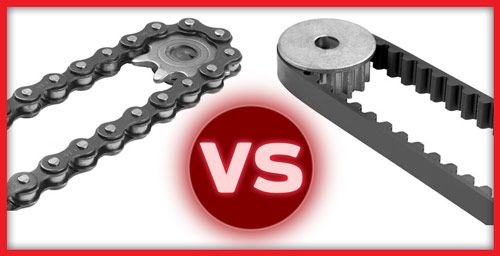

Belt Drive vs Chain Drive vs Jackshaft Opener Differences Explained

Understanding How Drive Systems Shape Performance

Performance Characteristics of Each Drive Type

- Belt drive: Smooth, quiet operation with low vibration

- Chain drive: Strong lifting capability with higher mechanical noise

- Jackshaft: Direct drive with stable torque and compact installation

Choosing the Right Drive for Daily Use

Maintenance and Wear Patterns

Smart Garage Door Opener Features, Connectivity, and Automation Trends

The Rise of Intelligent Garage Door Systems

Most Influential Smart Features in Modern Openers

- Remote control via mobile device

- Real-time door status monitoring

- Adaptive force calibration for smoother motion

- Motion-activated lighting

- Automatic close and safety alerts

Connectivity and Signal Stability

Long-Term Impact of Automation on Reliability

Opener Lifespan, Maintenance Needs, and Long-Term Reliability Factors

Key Factors Influencing Opener Longevity

- Door balance and spring condition

- Drive system efficiency

- Frequency of daily operation

- Electrical stability and consistent power supply

- Environmental conditions affecting mechanical tolerance

Maintenance Actions That Support Long-Term Performance

- Maintain proper door balance to reduce motor strain

- Keep moving components lubricated

- Ensure sensor alignment and clean signal path

- Monitor opener temperature during repeated use

- Check for unusual vibration or noise

Signs an Opener Is Approaching Wear Limit

Cost, Power, Noise Levels, and Choosing the Right Opener Motor

Matching Motor Strength With Door Load

- Door weight and size

- Frequency of daily operation

- Insulation and panel construction

- Desired motion smoothness and speed

Long-Term Value vs Initial Cost

How the Right Opener Choice Improves Daily Reliability

Why Compatibility and Calibration Matter

Service Information & Answers

Choose an opener based on door weight, size, usage frequency, and desired noise level. Matching the motor strength and drive system to the door ensures smoother motion, stable performance, and a longer lifespan.

Belt drive openers are typically the quietest because they reduce vibration and friction. They provide smooth motion and are ideal for homes where noise control is a priority.

Most modern openers last many years when properly installed and maintained. Lifespan depends on usage frequency, door balance, and consistent mechanical condition.

Common issues include slow response, sensor misalignment, increased noise, and motor strain. Seasonal temperature changes and frequent daily use often influence opener performance over time.

Yes. An underpowered or mismatched opener can strain springs, increase vibration, and accelerate wear. Proper compatibility ensures smooth, safe, and reliable operation.